Overview

SANDMAN® organizes, stores, validates, analyzes, and leverages the foundry's molding-sand data legacy for molding process optimization, using prescriptive and predictive data analytics. This enables the user foundry to move from reactive to proactive green sand control and management, and by corollary, reduce sand related repetitive casting rejections & additives consumption.

INTRODUCTION

Data is generated from several sources and locations in a Foundry and is often manually recorded and sometimes transferred to general electronic formats. As each day/shift passes, much of this data remains un-captured, or just recorded and forgotten, disappearing into reams of archives and remaining as random data.

Therefore, the first step towards Foundry 4.0 is the digitization and digitalization of a Foundry's data.

Back-of-the-envelope calculation indicate, the net cost of a 1% casting rejection in a 2000 ton/month foundry, in India, is approx.: 1.2 (INR 12 million) to 1.5 crores (INR 15 Million) per annum.

SANDMAN® DigiSMART helps you collate, structure, correlate, validate and analyze this data in a simple, straight-forward, and uncomplicated manner to get useful correlations of Sand test results with rejections.

Available on the Cloud, it enables Foundries to capture their data in standardized formats and provide meaningful corelations, which gives actionable insights from past trends and keep moving towards a more efficient and consistent process control. This, by definition, helps control process variability and thereby improves casting outcomes while optimizing the costly additives like bentonite, Lustrous Carbon, and silica sand itself, that goes into preparing the sand mold.

PRINCIPLES

1. Data Digitization & Integration

SANDMAN® DigiSMART efficiently captures, co-relates, validates and integrates a Foundry's sand data - regardless of volume and source into a structured repository.

Standardised, comprehensive and easy-to-use forms for data entry based on globally accepted nomenclature and foundry lexicon; thus, ensuring that data e ntered is correct every time!

Data can be entered directly through spread sheets (excel) or directly on the software and/or also through WiFi enabled Tablets and Mobile phones.

It also has IIoT sensors and SCADA handshake capabilities for on-line data capturing (optional feature).

2. Experiential Legacy

Historically, foundrymen have relied on the 'art' of experience and instinct based decision - making. However, there is a decreasing availability of domain-experienced personnel and skilled manpower. The new age sand systems which churn out huge volumes of sand, molds and cores and handle multi patterns with varying Sand:Metal ratios & rarely allow visual or 'feel' capabilities of the system sand.

SANDMAN® DigiSMART is designed especially for foundry green sand systems e nabling the Foundry to capture historical data bases as well as current data as-it-happens. It also has the unique feature of Annotation of daily and past experiences to build a knowledge base that accumulates and institutionalizes a foundry's experiential insights. This means that valuable knowledge doesn't get lost with the movement of personnel and is available to all succeeding process owners, without limitation.

3. Accessibility

This Cloud-based software makes it easy to access data anytime, anywhere, without geographic or physical limitations.

There is no need for on-site installation and the state of your sand system can always be available w ith a few clicks.

This software mandates NO change in Man, Material and Machine .

4. Data Correlational Capabilities

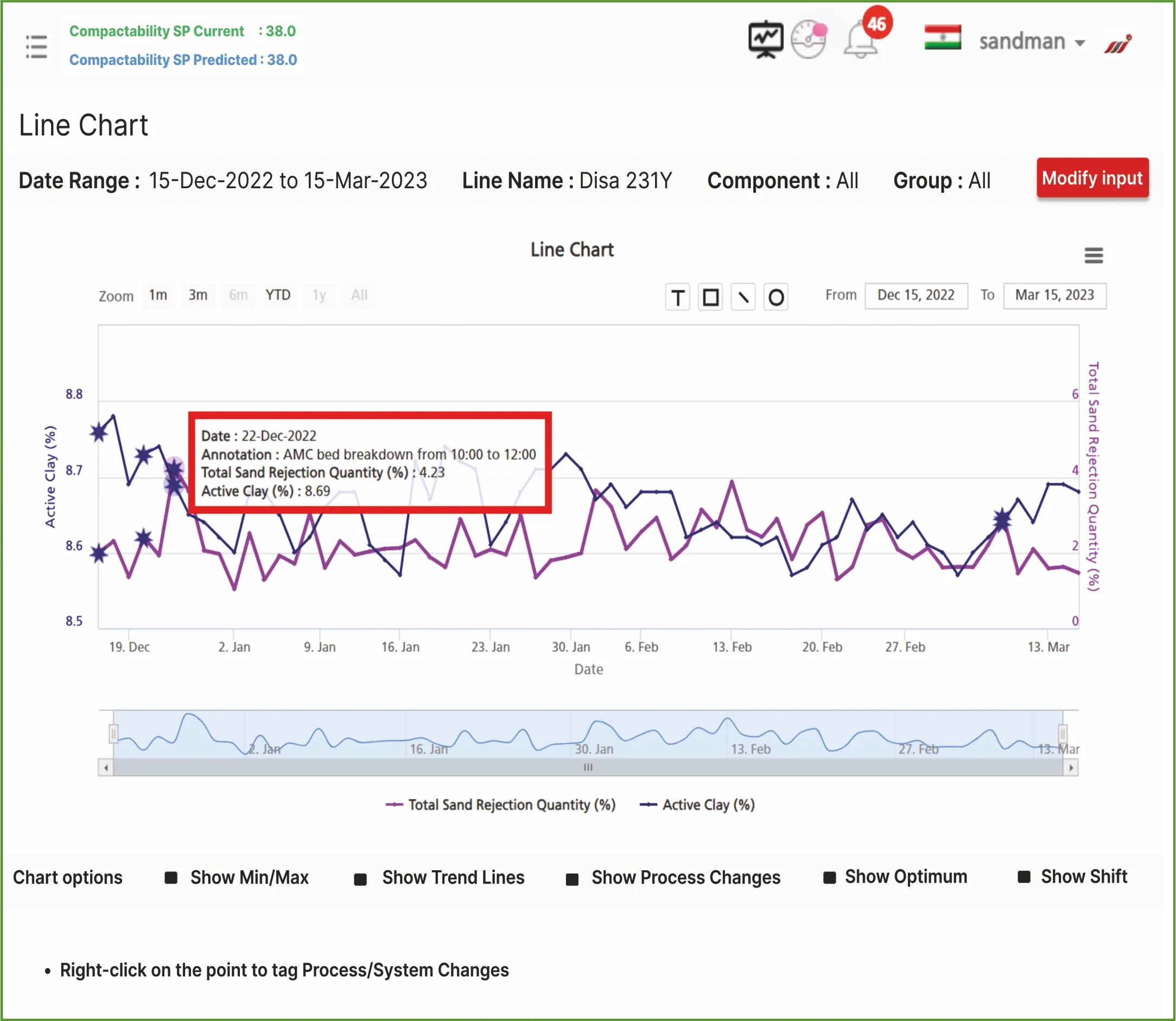

SANDMAN® DigiSMART: Allows for visualisation and correlation of multi-variate sand properties against casting defects over various time ranges, which can also be granular to individual components or casting groups, enabling useful actionalable insights to possible causalities of rejections.

Enables quick and insightful correlations between sand properties, additives, and rejections. The line charts can be easily customised across variable date and time series, multiple properties, rejection types etc., with directional support to understand causes of casting defects during the set period/s which can be chosen according to wish.

Salient

FEATURES

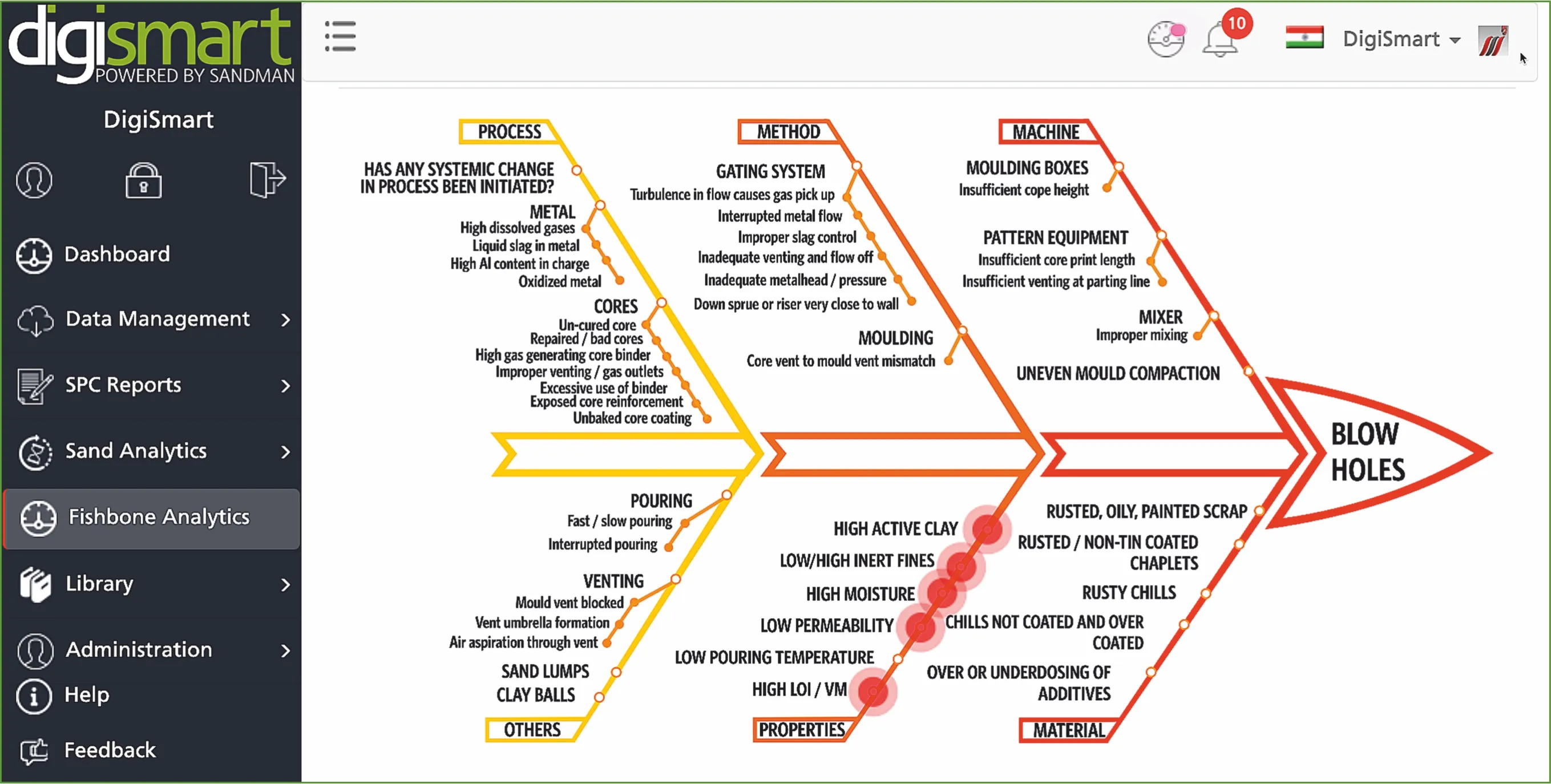

1. Root Cause Analytics

Process-Owners around the world and across spectrum of industries have understood the value of root cause analytics (RCA) using fishbone/Ishikawa diagrams, to zero in on probable cause of specific problems/defects. The setting-up of the analysis scenario is however time-consuming requiring relevant and extensive background data, often from various data sources.

SANDMAN® Digismart gives you a taste of the power of Machine learning based RCA to help you take informed decisions regarding your greensand processes. We have equipped DigiSMART with our powerful Correlation Influence Matrix which will help to rapidly pin-point problem areas/properties and take proactive corrective actions rather than reactive decisions; within few minutes if past data is available.

2. Dashboard

Our powerful Business Intelligence dashboard of Digismart gives you an updated view of your Green Sand system status and presents insights derived from available data in a way that's easy to understand and enables better informed decision-making and data analysis. The dashboard is specially designed for foundry MIS needs.

Quick metrics of production, rejections etc for selected time period.

Rejection percentage Chart at Foundry/Machining stage (Sand, Metal, core, other). Add powerful filters such as date, component, defect, Pareto (component, defect) for a day/week/month or other time period.

Pie Charts - Rejections (type and component).

You can directly download these graphs in high quality for your reports and presentations.

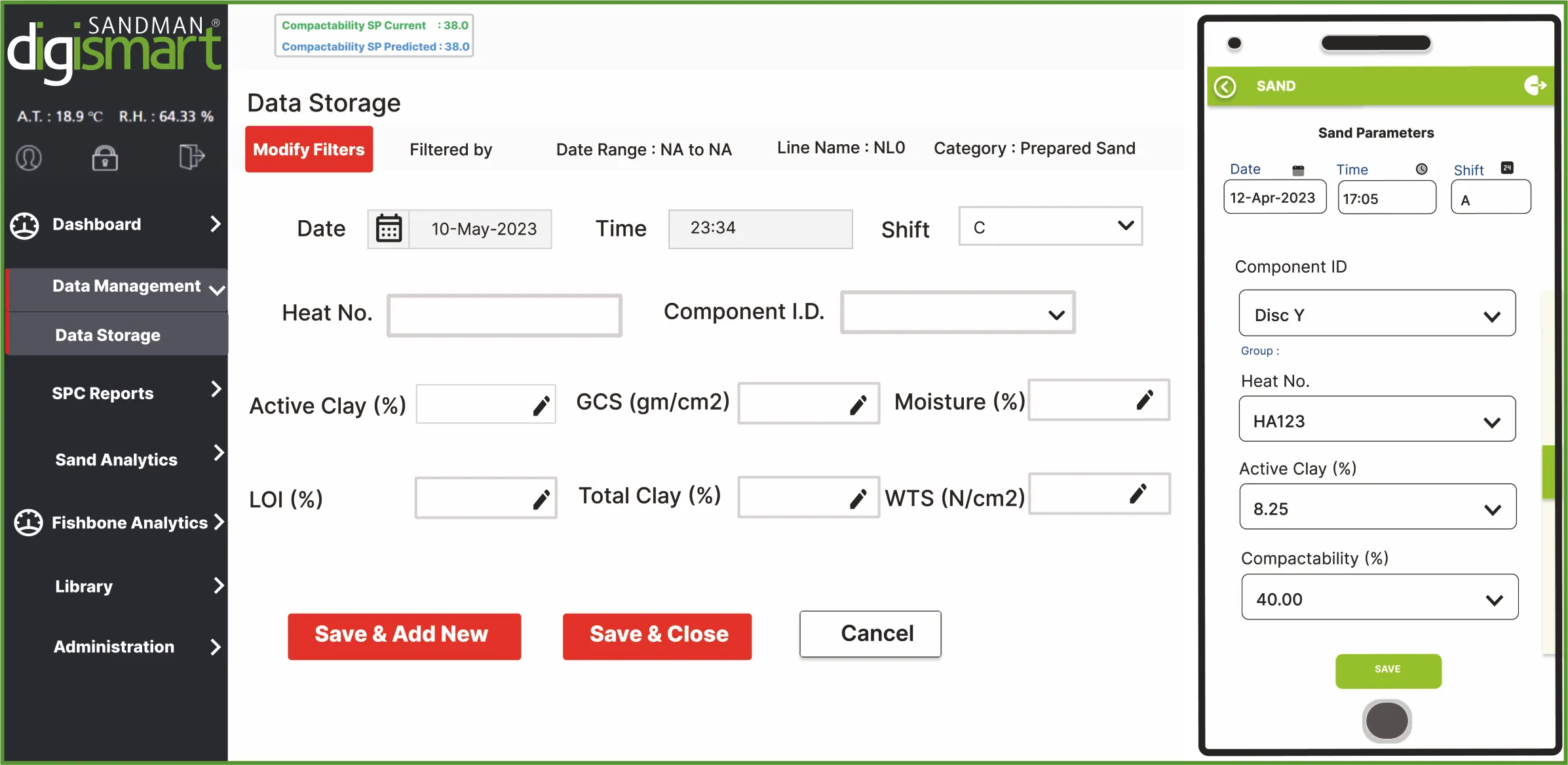

3. DATA MANAGEMENT

SANDMAN® Digismart offers comprehensive digitization and digitalization capabilities for foundries, providing a simple and straightforward way to manage sand, casting pattern, and process data throughout its life cycle. It's Desktop and Mobile Data management applications, along with the PLC via SCADA integration, enable the capture and integration of data from various machines in the sand loop, including the mixer, compactability controller, moulding machine, sand, moisture and ambient humidity and temperature sensors, and more*. This allows for data to be updated in SANDMAN® Digismart in near real-time, ensuring accuracy and accessibility.

OTHER KEY ASPECTS OF DATA MANAGEMENT:

- Data Validation - Powerful validation checks ensures data is segregated into clean and mismatched data.

- General Files - Upload pictures and PDFs of castings, defects or documents related to the development of new components, meeting notes and minutes, and more.

DATA STORAGE

4. ANNOTATIONS

As managers age, change and move on, their shop floor experience often moves out with them or is available in limited formats. To overcome this inevitability, a UNIQUE feature of ANNOTATIONS is offered by SANDMAN® Digismart which enables you to record shop floor, System-Sand related experiences and events so as to assist you in future situations for informed and legacy data-based decision making.

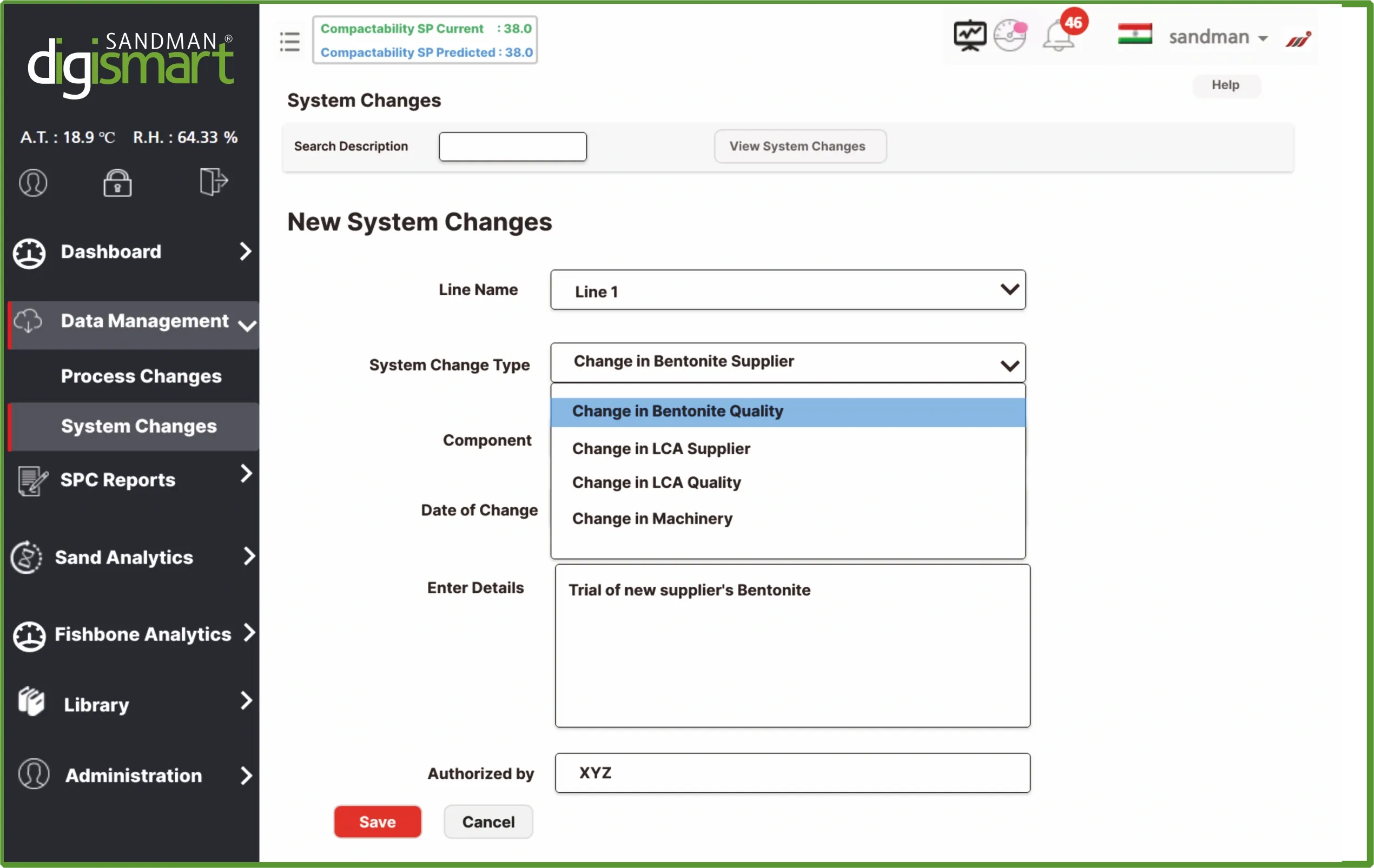

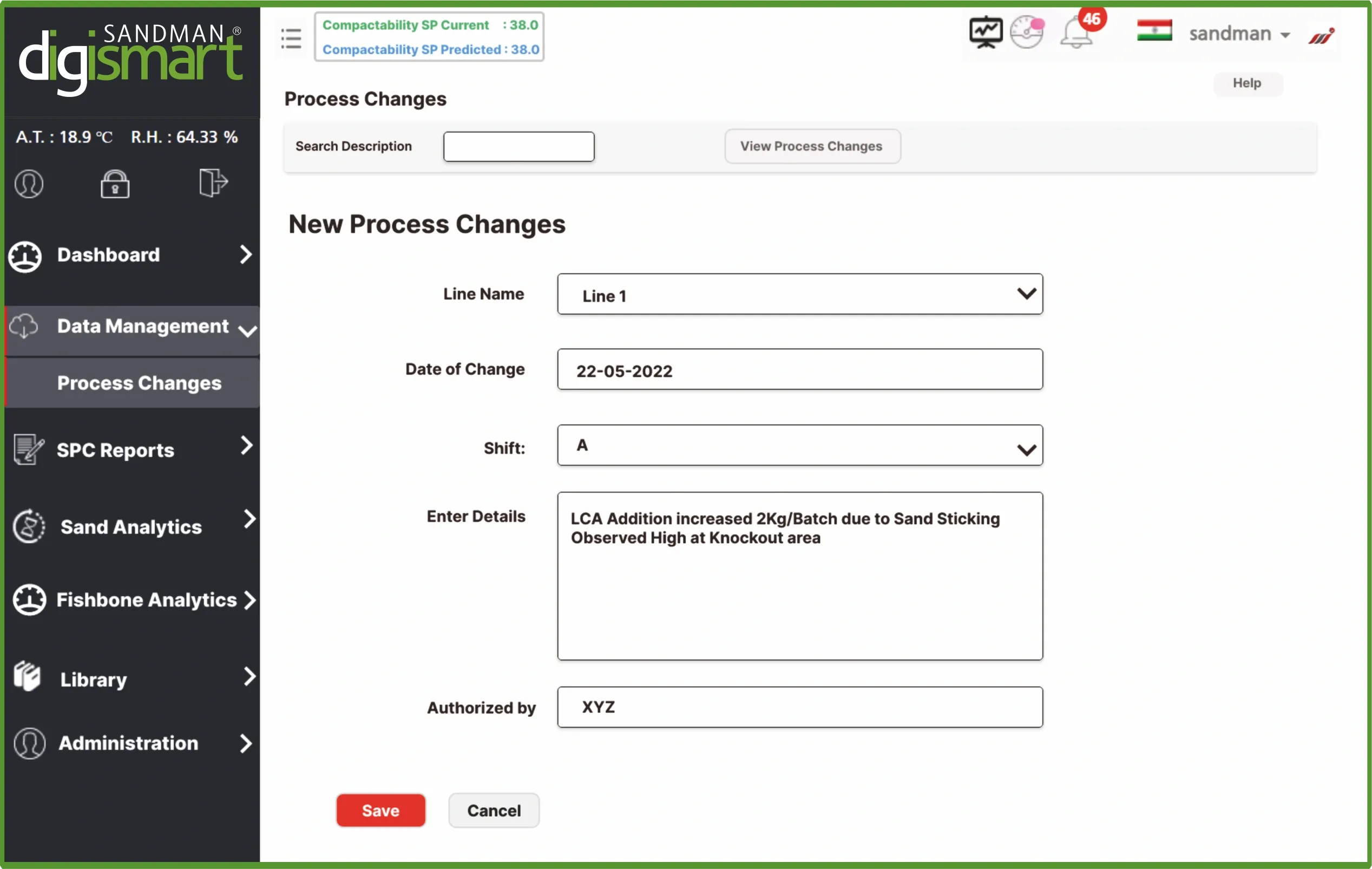

SYSTEM CHANGES

PROCESS CHANGES

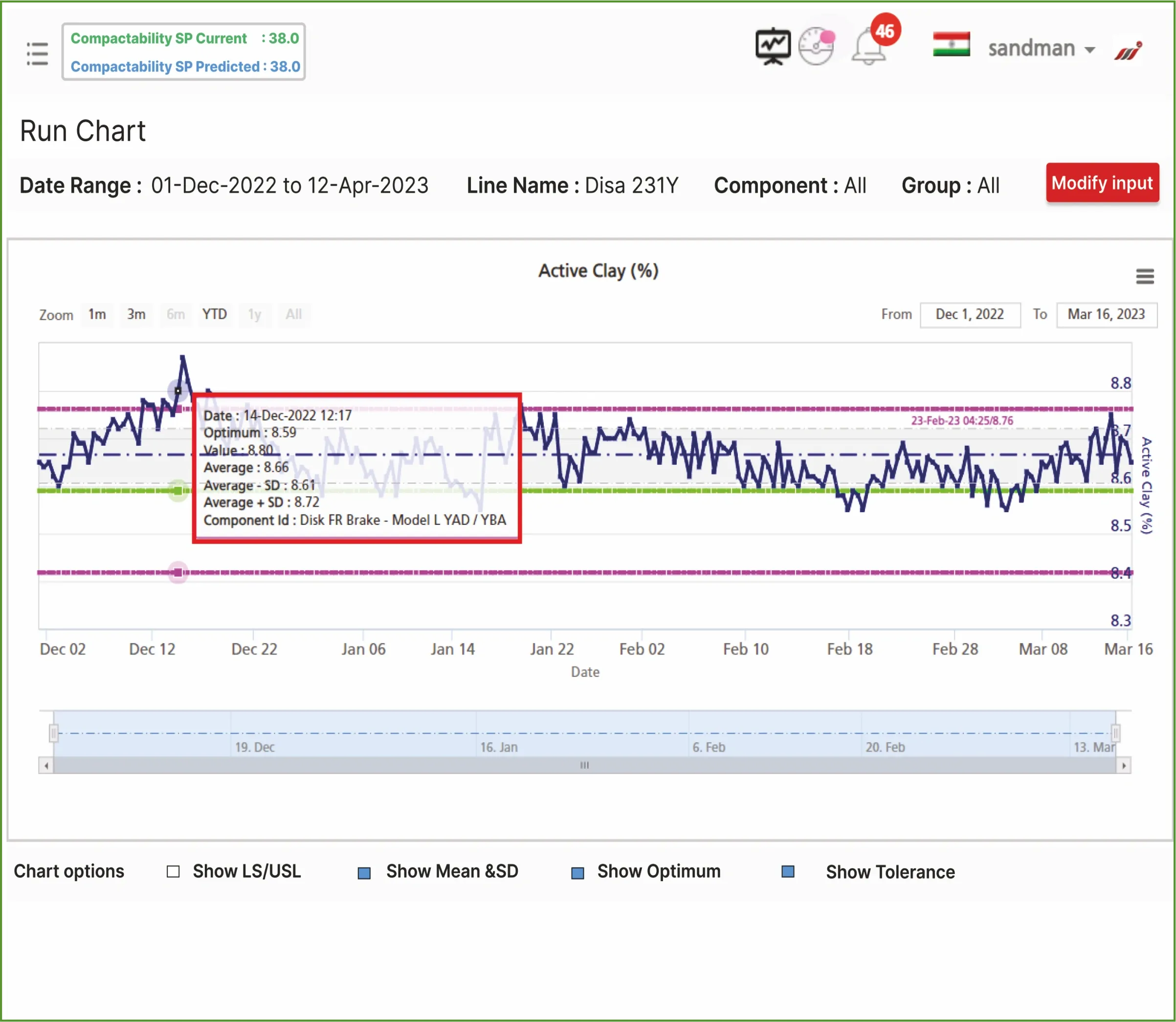

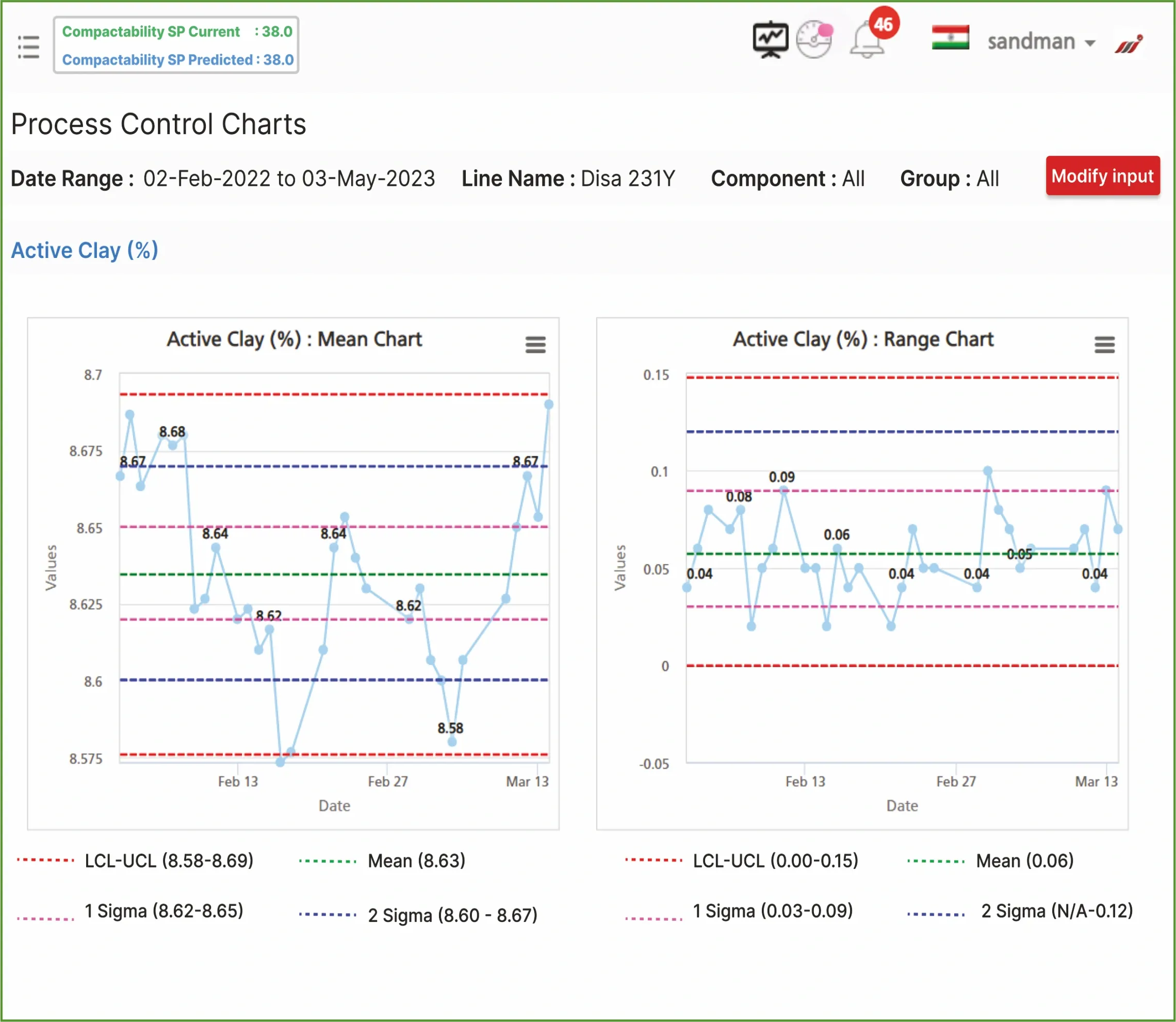

5. SPC Tools (Statistical Process Control)

SANDMAN® Digismart incorporates a comprehensive suite of Statistical Process Control (SPC) tools, designed to enhance quality control, optimize efficiency, and minimize variability in foundry green sand process control.

These tools enable real-time statistical analysis of sand parameters against rejections by type, component, or group, across unlimited time-frames. These features are fully integrated with the alert management system, ensuring timely and actionable notifications when specific conditions are met.

Some SPC tools available in Digismart include:

1. LINE CHART

2. RUN CHART

3. PROCESS CONTROL CHART

4. PROCESS CAPABILITY METRICS

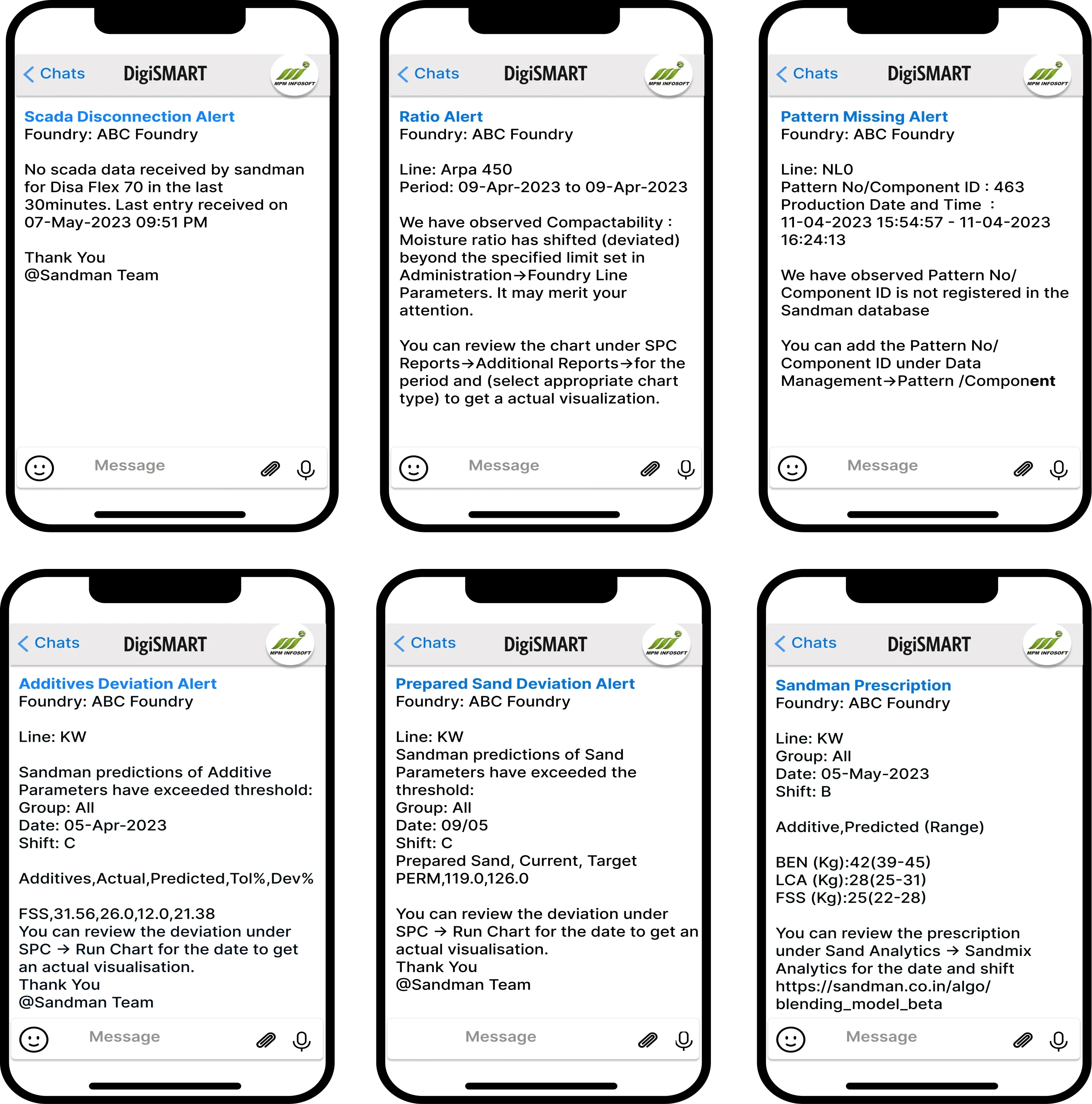

6. Alert Management

SANDMAN® Digismart smart alerts are generated using a complex system of pre-defined rules and algorithms that employ data analytics techniques such as anomaly detection and pattern recognition to analyse data and identify any deviations from user-defined process control boundaries. These alerts are triggered when specific conditions are met, allowing for timely intervention and corrective action. The alerts can be delivered via multiple channels, including email, WhatsApp, SMS and in-app notifications, ensuring that users stay informed, alert and can take timely corrective measures.

Common examples:

- Security/User behaviour alerts

- Process, sand properties, additive addition and quality deviations, and many more system alerts

- Performance alerts - These alerts notify users of performance issues or outages.

- Analytics alerts - These alerts notify users of trends or changes in key metrics.

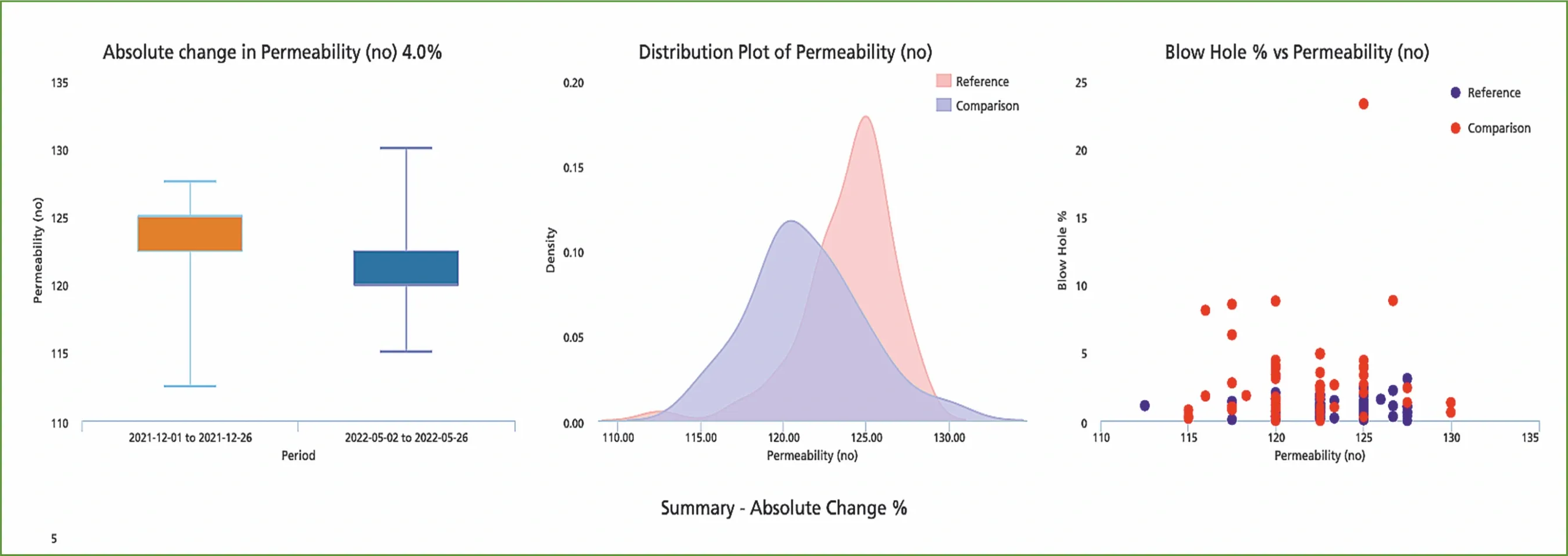

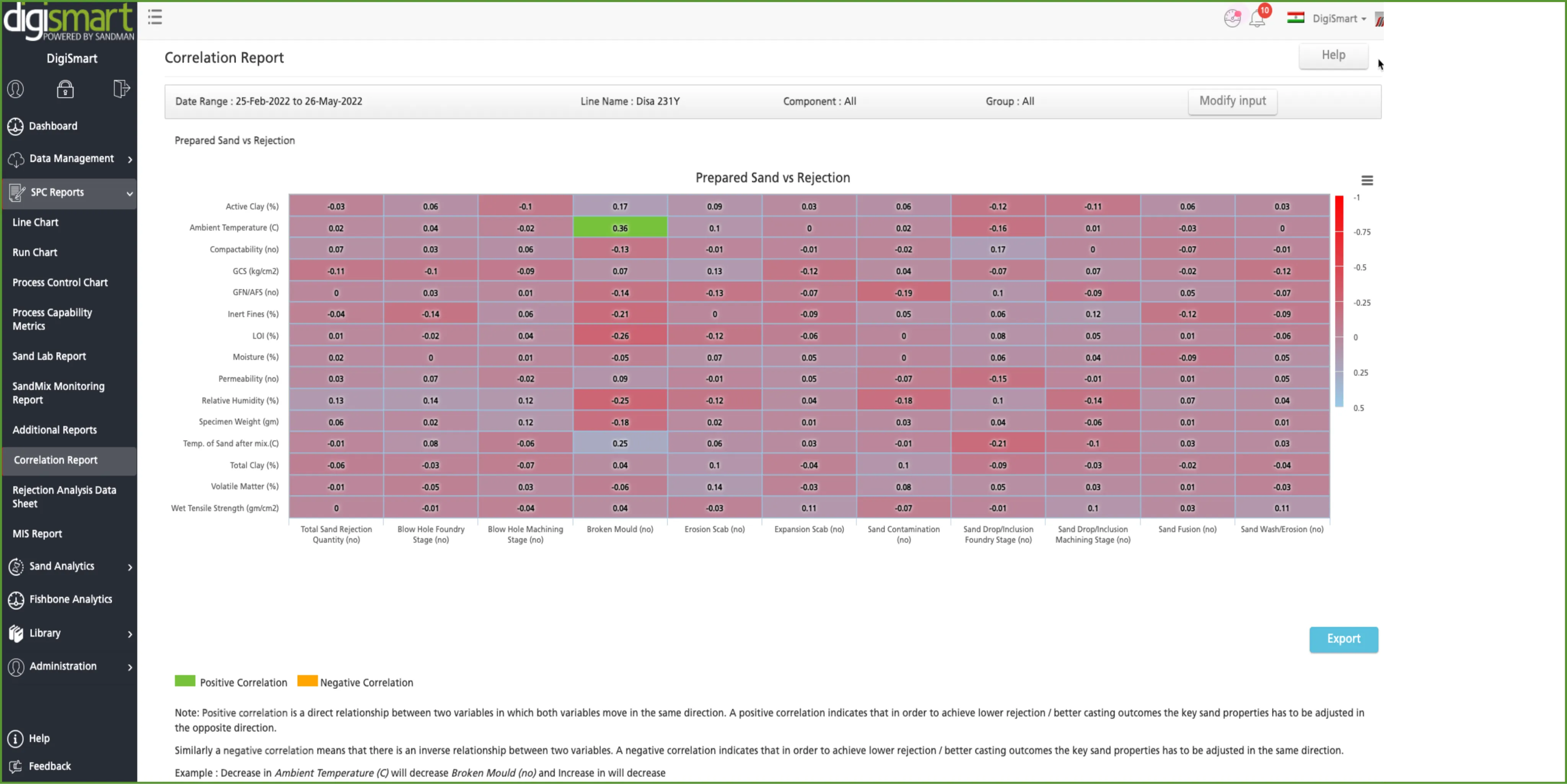

7. Co-Relation Analytics

The SPC tools will aid run-time statistical analysis of how sand parameters are performing against rejections by type, component or group over an unlimited time range.

Correlational Influence Matrix - is an algorithm which correlates Prepared Sand v/s Consumption, Rejection v/s consumption, Prepared Sand v/s rejection to give against rejections by type, component or group over an u nlimited time range.

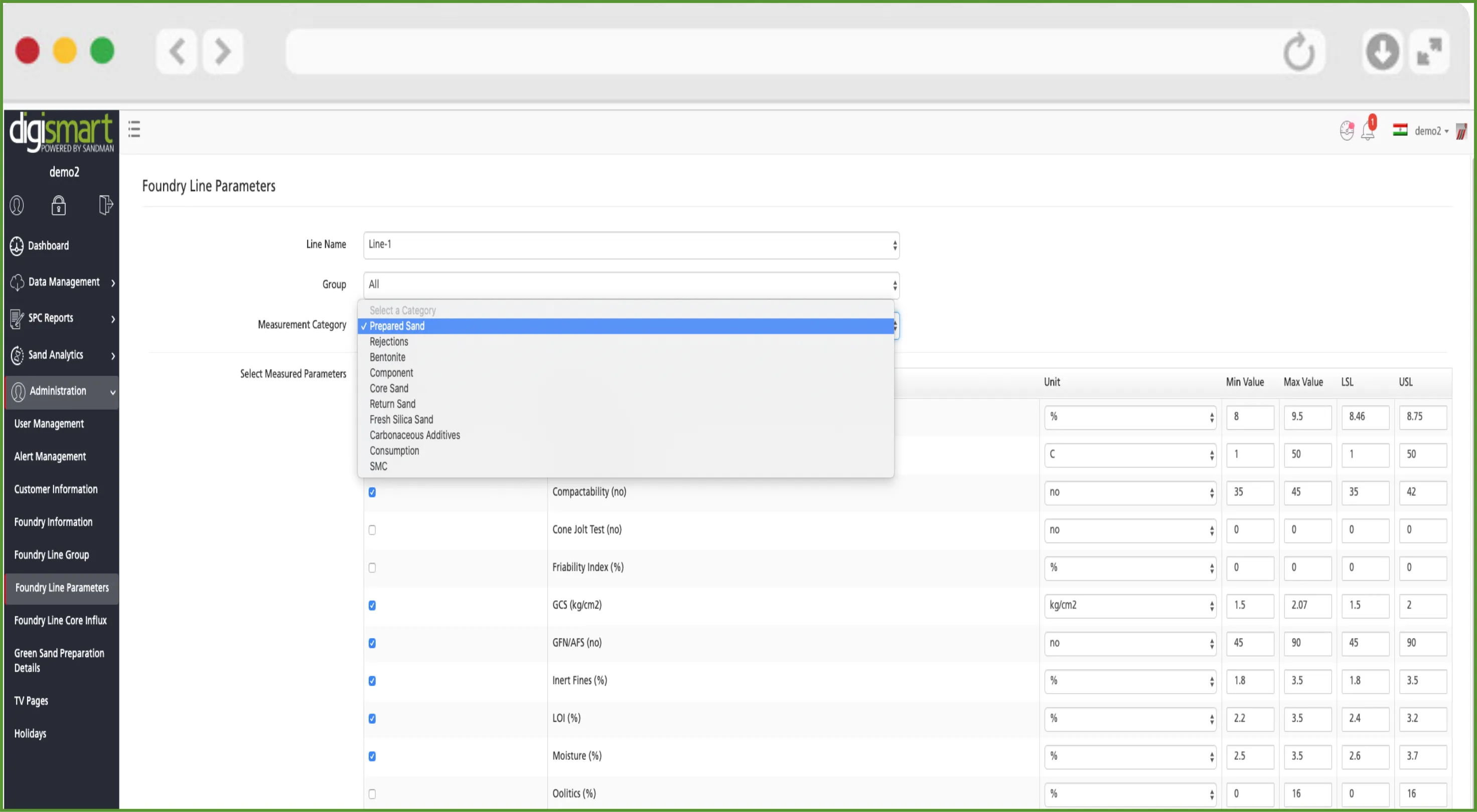

8. Administration

SANDMAN® Digismart has provisions which allows you to uniquely customise the software to suit your Foundry and preferences. A Foundry can add/remove users, configure your foundry line, sand categories and parameters as per your requirements.