SANDMAN® saves more than INR 17Mil. in costs by reducing sand rejection by 72%

Goals:

To reduce the sand related rejections and estimate the savings that can be achieved by controlling the rejections.

Background

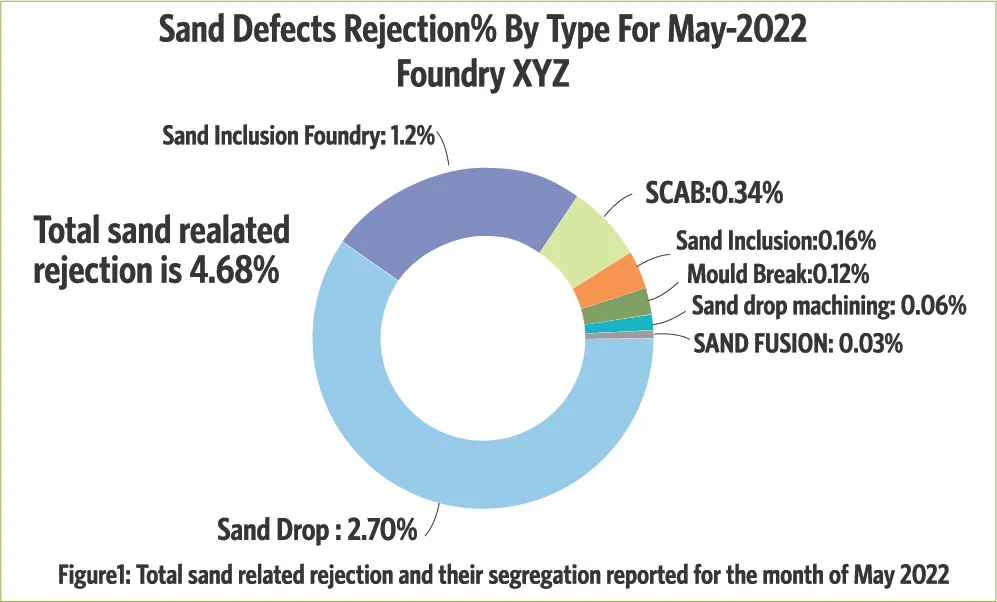

Before SANDMAN®, one of our foundry clients, with a production capacity of approximately 26,000 tonnes yearly, experienced sand defects rejections of 4.680/o. They are experts in producing iron castings, mostly nodular iron. Their average bunch weight and sand to metal ratio are 83kg and 9.03 respectively. Additionally, their average core weight is 2.4kg. The detailed segregation of the types of defects is mentioned in the Figure l.

After implementing SANDMAN ® , the foundry was able to monitor, analyse, and by using SANDMIX "dose-byneed" prescription of sand additives; succeeded in reducing their sand-related rejections and achieve cost savings.