Temperatures are Rising - Is Your Casting Throwing a Tantrum

As temperatures rise across the Indian Sub-Continent (and elsewhere in the world) the green sand molding process in foundries undergoes subtle changes. The surface temperatures of the sand mold rises over what they were in the months of November to mid-March. Hot winds blow across the landscape to which the factory floor is no exception in terms of rise in the ambient temperatures. Ground water levels recede and more solids and salt concentrate in the water used in molding mix. As this subtle but important phenomena unfolds, it creates the following cascading impact on the casting process:

- Return sand residual moisture decreases (unless compensated by water cooling/sprinkler add-ons)

- Residual moisture in hoppers decrease

As return sand moisture decreases, sand temperatures stay relatively higher than usual, resulting in inhibited Bentonite bond. This may result in scabbing and sand drop increase.

- Bond generation from the residual clay in the return sand slows correspondingly. Maybe advisable to increase wet mix time in the mixer.

- Sand surface friability rises (rise in friability index)

- Mold moisture and compatibility indices change (on the lower side)

Compensatory moisture additions, without change in the Bentonite dosages set before the weather patterns changed, may create a mismatch resulting in increased free moisture.

If the water used for molding mix is from bore wells or untreated water sources, the solids/salts in the water increase as ground water levels drop. This increase in water hardness can and will cause the Bentonite to become passive, compromising it’s bonding capabilities.

As bonding capabilities reduce, free moisture increases and may result in increased explosive penetration and rough surface.

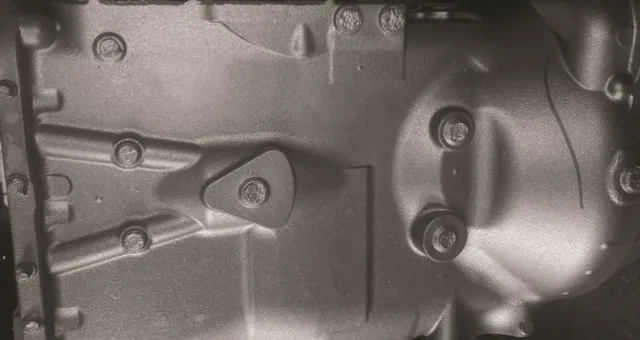

All this and more physio-mechanical imbalances in the molding process may cause increase in surface roughness of castings as one example of casting impact.

Different Geographies have different impact on the molding sand.

“Green Sand is just as complex as we make it. Other than that it is quite simple and simply needs to be treated as we would treat our own well-being on a daily basis. Don’t overdo or under-do the additive dosages. Just observe the return sand and add each additive on a need basis, not as a daily one-dose-for-all-problems kind of prophylactic.”

Deepak Chowdhary For more on foundry sand molding and leveraging data analytics for reducing casting defects and increasing profits click here .