What is the REAL Cost of Casting Rejections?

Reclaiming Lost profits of Casting Rejections - leveraging the power of data analytics

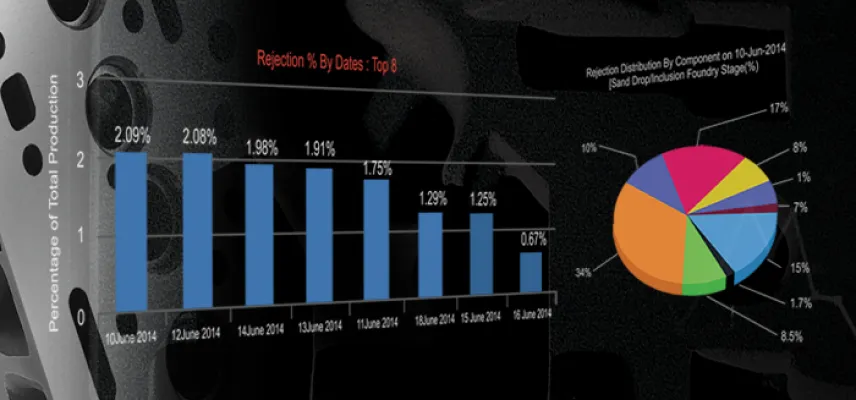

By a back-of-the-envelope calculation, the cost of a 1% green sand rejection in an entry-level 24,000 ton per annum foundry could approximately range from: INR 12 million (US$ 175,000) to INR 15 Million (US$ 220,000) per annum.

In these times of fast changing economic scenarios, business eco-systems & the resultant increasing pressure on business sustainability and relevance; casting rejections and their control in foundries assume huge significance.

Consider the following:

- All foundries, Globally, suffer rejections. Some suffer more, some less.

- Rejections are repetitive. So, losses are repetitive.

- Analysis of castings defects is always reactive and post facto. Post mortem.

- Rejections could range from 0.5% to 20%. depending on several operational and process control conditions and attitudes.

A simple calculator of Casting rejection costs could be:

- Casting Tons/ annum (say: 2000 tons/annum X percent scrap (say: 1%)) = 20 tons x 12 months = 240 tons

- Selling price (say: Rs.85,000/ ton ( raw casting)) = 240×85,000 = 20.4 million

- Scrap value: (say Rs.25,000/ton) 240 x 25,000 = Rs. 6.0 million

- Lost profits & cost to bottom line : 20.4 -6.0 = 14.4 million Rupees

Once the foundry accepts the back-of-envelope calculation, the next simple question is how can we control this cost as effectively as possible, not only today but consistently and sustainably?

Rejections are inevitable due to the ‘noise' of the casting process. But, their extent can be controlled by minimising the ‘noise' using process control enhanced by the now available tool of data analytical decision support from historical data. The answer is to graduate from reactive and often linear co-relational effort to analyse repetitive incidences of rejections; to multivariate predictive, proactive and forward looking action using data analytic driven decision support for sand related defects.

The world has already adopted data analytic decision support in so many ways that touch our lives everyday. For example:

- Navigation in all modes of travel: Land, sea, air and space.

- Consumer behavioural retail management of stocks and discounts to optimise inventory and discount according to need and seasonal positioning.

- Jet Engine performance to save fuel and also lives by predicting engine performance before serious malfunction.

- Entertainment: forecasting personalised customer preferences and predicting optimum stock levels of titles of movies and books.

- Predictive failure of critical machines: example, Turbines.

The list is huge and growing each day as more and more industries move to adopt data analytics and benefit from their historical data to optimise their profits and prevent repetitive mistakes. Mistakes which can often be very serious, damaging and even result in the obsolescence of the Enterprise to more agile and technology updated and forward looking competitors.

Consider this:

In many industries even today the accent on cost reduction often translates to: “Reduce the vendor rates”

Sure, this is an important function of the purchase department. But, it is also important to evaluate the priority of reducing preventable waste, equipment failure and downtime, serious and costly equipment damage.

On the positive side; use of data analytics minimises inventory, maximises customer choice focus. Predictive discounting patterns also minimise loss and wasted costs of giving too much discount at the wrong time to too little at the most opportune time.

So, please consider: can your foundry afford the cost of even a 1% preventable rejection?

For more information to the answer to this question please visit: https://www.mpminfosoft.com/products/sandman

SANDMAN - The world's first data analytic driven decision support software which enables foundries to optimise their molding sand and thereby reduce casting rejections, reclaiming significant repetitively lost profits!